Several days ago my old Monsanto soybean site in Illinois hosted a special visitor – Flat Aggie! Aggie has been traveling across the country visiting different farms and learning all about agriculture. Her story gets shared to over 540 students in classrooms in Illinois, Kansas, Florida, North Carolina, California, and Arkansas! Keep reading to see what she learned about soybean production!

Ashton, IL

Howdy! Aggie here, reporting in from the small town of Ashton in northern Illinois. The land out here is almost as flat as I am and the temperature is surprisingly warm for March. There isn’t even any snow on the ground!

After visiting so many farms and meeting so many awesome farmers, I thought I’d take a trip to visit a soybean production facility to see what happens to seed before it ends up in one of those farmers’ hands. Here’s what I learned:

Scope

In Ashton I learned that Illinois farmers plant close to 9.8 MILLION acres of soybeans each year! An acre is about the size of a football field. Employees at the Monsanto soybean production site I visited told me the average number of soybeans farmers plant per acre is about 140,000. Can you do the math to figure out how many soybean seeds Illinois farmers sow each year?

Seed Production

But where does all that seed come from? It turns out seed companies like this one need the help of farmers to produce enough seed for everyone to plant! All through the summer this soybean site works really closely with over 150 farmers, just like the ones I’ve been meeting, who agree to grow fields of soybeans just for them! That means instead of those harvested seeds being sold at a grain elevator for use in things like animal feed, they end up at facilities like the ones here in Ashton.

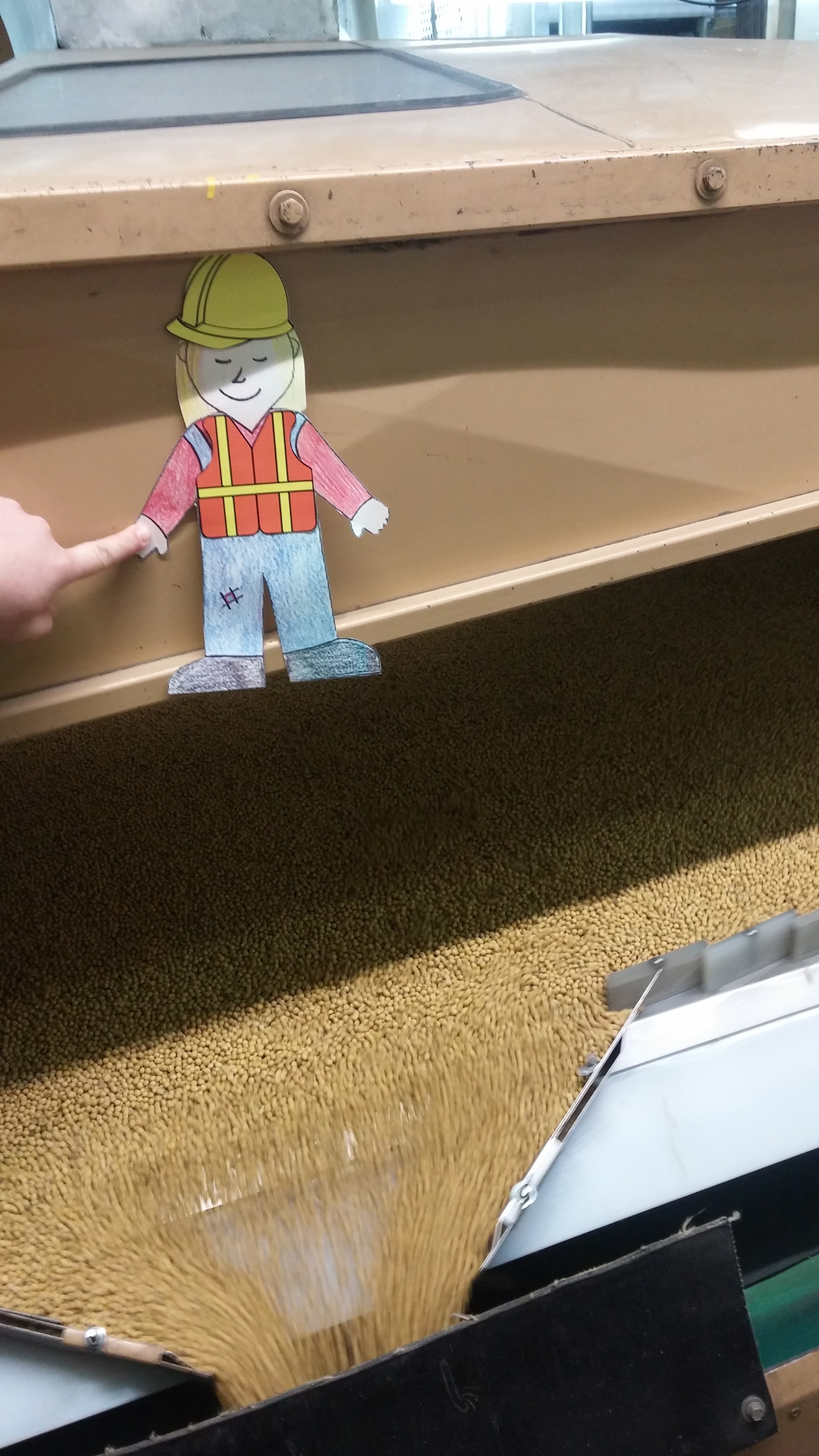

Big trucks with 18 wheels haul loads of soybeans to this site where they’re transferred into storage bins like the ones behind me in the picture above. I thought maybe the seeds went straight into bags for the farmer, but boy was I wrong!

See all those pods and stems?! That’s how the seed arrives here. Farmers definitely don’t want that in the bag because it can clog up their planters! Before the site can put this seed in a bag, they need to clean it up.

First the seed runs through a series of screens like these. The pods, stems, rocks, and other big debris will stay on top of the screen while really small debris falls all the way through. In the middle, the good seed that farmers want moves on to the next step…

Color sorter

Next the seed runs through this thing called a “color sorter.” Actually, they run through so fast they’re just a blur in the picture! The soybeans flow one-by-one past tiny cameras that determines if the bean falls within a certain color range. If the color isn’t quite right, a small blast of air spits it out! This is a way to remove beans that are diseased (see picture below!) as well as seeds that aren’t supposed to be in there such as weed seeds or corn kernels.

These are the kinds of diseased and discolored soybeans that the color sorter removes!

After the color sorter, the soybeans run across something called a gravity table. This is kinda like a tilted hockey table that vibrates and has a little bit of air blowing up from underneath. Low density beans that they don’t want flow to one side and go to cull while the rest are kept and move on to the next step!

Gravity table

I got to get up close and personal with the controls to adjust the gravity table!

Some of the soybeans are packaged at this point, but sometimes they take an extra step and get a seed treatment applied. The seed treatment is sorta like a shield that protects the seeds from insects and diseases while they’re in the ground. I think it’s pretty!

NOW the soybeans are finally ready to get into a bag or box and into the hands of farmers! There are many different brands and varieties of seeds for farmers to chose from and they’re really good at figuring out which ones will work best for them. The bag you see below has enough seed in it to plant about 40 acres! Remembering back to the average planting rate of 140,000 seeds per acre, can you figure out how many seeds are in this bag?

Thanks so much to my hosts in Ashton for showing me around their Monsanto facility! I gotta say, there’s a lot more to this seed production stuff than I imagined. It was fun to make this pit stop, but I’m ready to get back out to the farms! If you have any questions about Monsanto or their seeds you can check out Discover Monsanto, or just ask Hannah in the comments below!

2 Pingbacks